Many coatings and thin films are used in modern industry. The performance of these coatings can depend on their character at the micron and nanometer scale. Whether they are homogeneous or separate into different domains, whether they are continuous or perforated, can determine whether they function properly or not. The AFM is a valuable tool in measuring such characteristics of films and coatings.

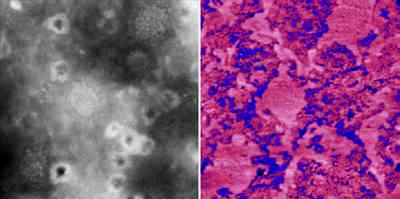

Aluminum beverage cans are lined with a polymer material to protect the contents from direct contact with the aluminum. This seemingly simple application reveals some complexity when viewed in the Atomic Force Microscope with phase imaging.

Dark is low. The right hand image is phase data.

The different colors/brightness levels represent

different material domains. Note that these

material regions are not associated with specific

features in the height image. The polymer material

on the inner surface of the beverage can has separated

in application into different regions. Further analysis

would be necessary to determine if this separation is

associated with performance problems in use and

whether it is characteristic of the material itself or

produced by the production process.

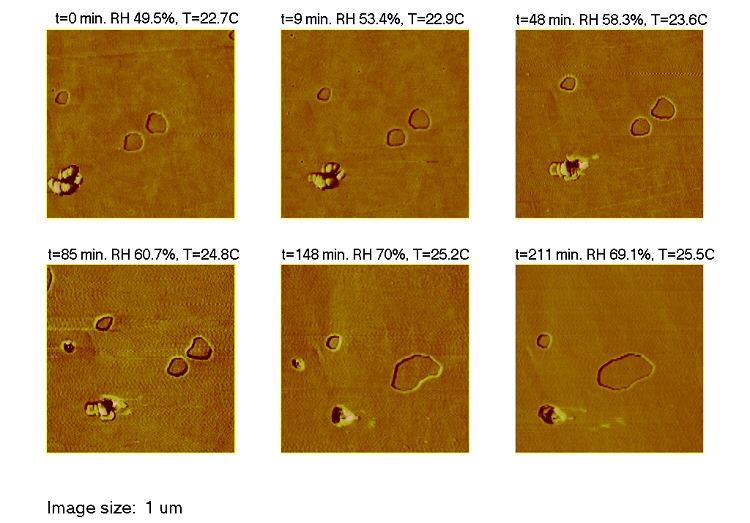

Lactose is a common excipient used in medications. Lactose is also a component of films used to coat medicine tablets. These coatings make the tablets smoother and less likely to start dissolving in the mouth or esophagus, slowing down the enzymes that dissolve them until they reach the stomach. As such, they are important to proper functioning of the medication. AFM analysis can be a vital tool to understanding how these coatings work and ensuring that they work consistently every time.

These are just two of the films/coatings we have examined in the Atomic Force Microscope. Whether it’s studying the surface roughness and weathering of paint films, the effects of chemical exposure to protective coatings, or complex biofilms, Atomic Force Microscopy can help make your films and coatings better.