Atomic Force Microscopy (AFM) has several characteristics that make it useful for biomedical applications.

- It can reveal smaller structures than are resolvable in optical microscopes.

- It provides a true three dimensional map of surfaces

- It can be done in air and in liquid (unlike electron microscopy)

- Wide varieties of samples can be examined.

Bio-Molecules

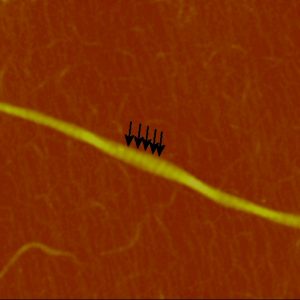

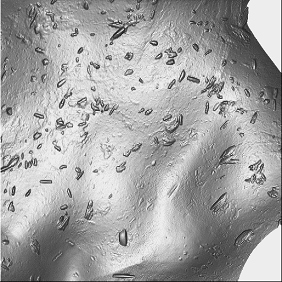

One area of biomedical application is in the measurement and characterization of bio-polymers such as proteins and DNA. Atomic force microscopy can be used to image such molecules as collagen:

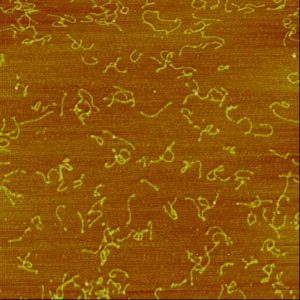

And individual monomers:

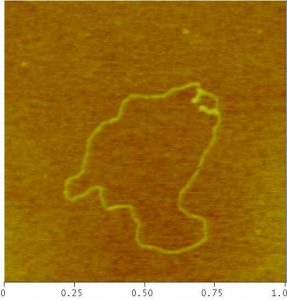

And DNA:

Once an image is captured, we can make measurements or perform other characterizations on the molecule.

While many people are aware of the role of DNA in gene splicing experiments, there are many more uses in the biomedical field. Recent work by the Karolinski Institute uses DNA nanoballs as a diagnostic tool for identifying pathogens. In this process a refined version of the LAMP DNA amplification process would be used to create DNA nanoballs. The nanoballs would then pass through narrow channels and detected as they pass between two electrodes. AFM can be used as a tool in developing the process, directly measuring the size of nanoballs produced by the modified LAMP process to ensure the sensitivity and accuracy of the test.

Pharmaceutical powders

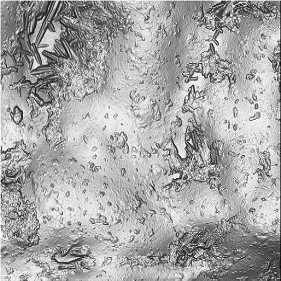

Another application of AFM is in measuring pharmaceutical powders such as those used to make pills. The size and shape of powder particles affects how quickly they dissolve and can have other effects on their usefulness. AFM is a valuable tool in measuring the size and shape of such particles.

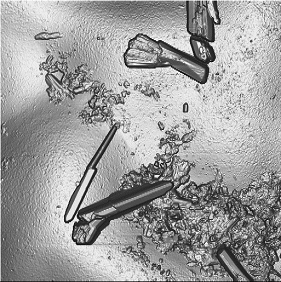

Pharmaceutical compound in a polymer matrix. The pharmaceuticals form crystals while the polymer is amorphous The crystals can vary in size and shape, as can their distribution–sometimes dense, sometimes sparse. Production process variables can affect the size, shape, and distribution of the crystals which in turn can affect therapeutic effect. AFM provides a tool to understand what is happening and why some processes work better than others. This helps both researchers and manufacturers produce a better quality product more quickly at less cost.

Polymers for use in prosthetics and instruments.

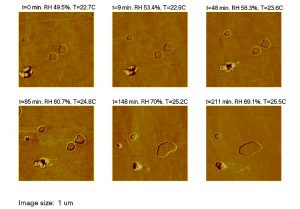

Polymers for use in medical applications must meet extremely stringent standards. The surface characteristics, and how those characteristics change over time, can be vital in how well those medical devices work. The internal structure and composition of most polymers, including those used in the medical industry, is very complex. Materials can “bloom” to the surface or can migrate across the surface, leading to unexpected changes in the function of medical devices. Some of these changes can happen with a device simply sitting in storage. With an atomic force microscope, one can test spots on the surface of a device and examine them again at the same spot from time to time to determine if changes are taking place. This information can help determine the life expectancy of devices and components.

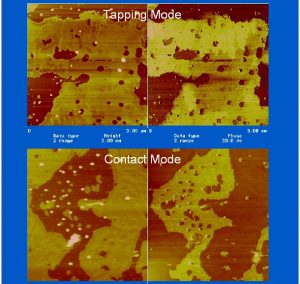

Coatings and thin films

Coatings and films are vital to the proper function of many devices and components in the medical as in other fields. With AFM, one can examine coatings to detect material differences on the nanometer to micron scale and check whether the coating is continuous or perforated. This can be important in the proper function of medical devices and instruments. These are just a few of the ways in which AFM is used in the biomedical industry.

Nanoparticles

Nanoparticles are used in the medical industry. For example, a wearable sensor that detects C Reactive Protein (CRP–an indicator of inflammation) in the body uses gold nanoparticles to carry CRP antibodies. AFM can be used to check the size and uniformity of the particles ensuring the reliability and accuracy of the sensor.

Other NanoMaterials

Hydrogen sulfide is necessary for certain metabolic processes but excessive amounts, like with most things, is harmful. One of the most common disorders that involve excessive hydrogen sulfide is Down Syndrome. Recent research show that specific carbon nanomaterials can be used to convert hydrogen sulfide into its metabolites that offer many favorable functions. AFM can be used to examine samples of the nanomaterials and ensure consistency of the production process ensuring quality of the product.

Use in treating Osteoarthritis

One example of the way in which nanomaterials might be used is in the treatment of osteoarthritis. For example liposomes can be used to encapsulate medications for more precise treatment. Chen, Kuo, et al in animal studies showed that libosome encapsulated rapamycin can have significant anti-inflammatory effects in animal tests. TappingMode or PeakForce Tapping AFM in liquid can be used to measure the size and shape of such liposomes to ensure quality and maximize therapeutic effect.

Another nanomaterial used in treatments are mycelles. These are amphiphilic structures. They have a hydrophobic core surrounded by a hydrophilic shell. As with most nanomaterials particle size is a critical measure of the production process. Materials such as mycelles can be measured by depositing them on mica and measuring the height of the bumps that each particle produces on the atomically smooth mica surface. This can be exacting work requiring special sample handling and preparation techniques. Advanced Surface Microscopy has done similar work measuring nanomaterial particle size for a number of different clients.

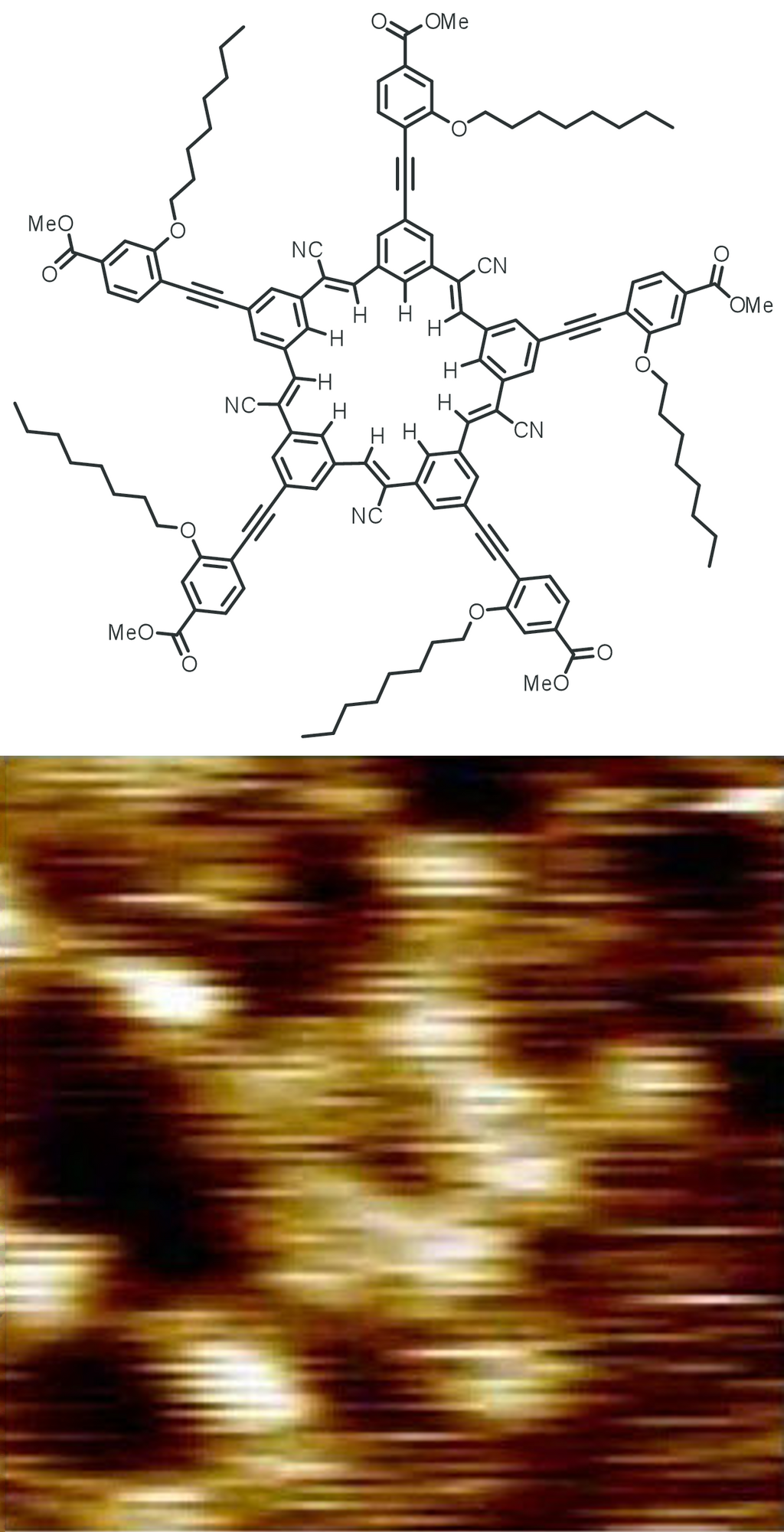

Next there are dendromers. Dendromers are large molecules with a repeatedly branched tree-like topography. Dendromers consist of three components, the core, the branches, and the shell. The shell provides a hydrophylic surface for transport allowing the core, which can be hydrophobic to carry a hydrophobic cargo. The number of branches in the treelike structure determines the size of the dendromer. Scanning probe microscopy can be used to examine the structure of dendromers as shown in the following illustration:

One of the first medical applications of Dendrimers is in the product VivaGelTM Which can be used to help prevent the transmission of HIV and HSV.

Another type of nanoparticles are exosomes. These are bilayer phospholipid bilayer vesicles that are endosome derived and membrane bound. They are generally 50-150 nm in size. They can be both naturally occuring and engineered. Their payload can be proteins, bioactive lipids, or nucleic acids such as DNA, mRNA, etc. Several studies have shown potential therapeutic uses in treatment of osteoarthritis. As with other nanoparticles, AFM can be used to examine the size and consistency of size of the exosomes.

For further information and to discuss your application, please contact us.