AFM Analysis of Metals

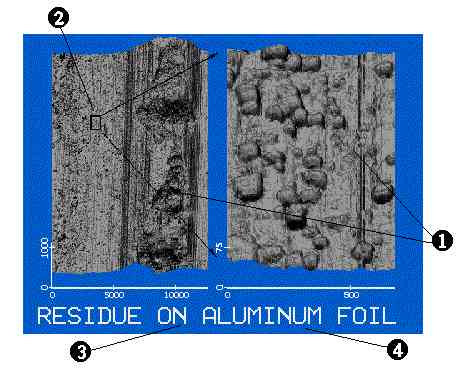

Atomic Force Microscopy is commonly used to examine the surface structure of metals. Whether it’s coatings, contamination, or corrosion, the Atomic Force Microscope provides a tool for better understanding.

Coatings

Metals are coated to control friction, to protect the metal from the environment, to protect the environment from the metal, and for other purposes. The performance of the coating depends on the structure, particularly when the coating is a thin film where irregularities can easily become perforations.

Finish

The surface finish of a part can be a vital factor in how well it works. The Atomic Force Microscope, by making a three-dimensional map of the surface, allows detailed examination of the surface finish. Both quantitative analysis of surface roughness and bearing plots can be performed. The AFM can measure surface roughness over a very wide dynamic range: from Ra = 0.03 nm to 500 nm

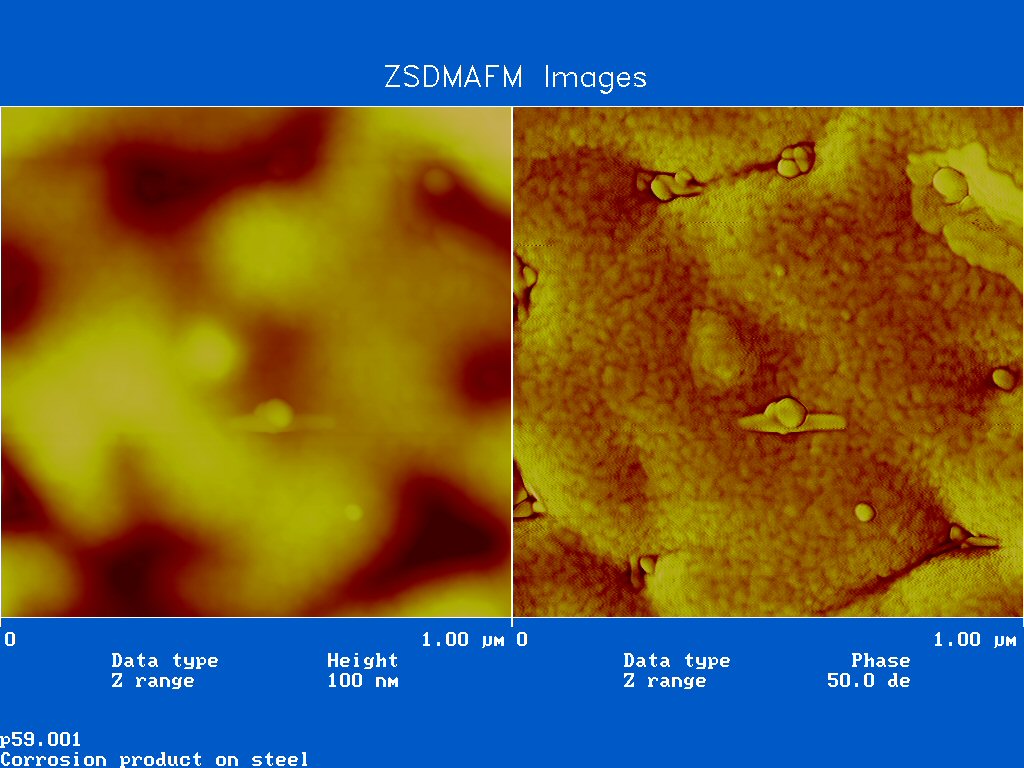

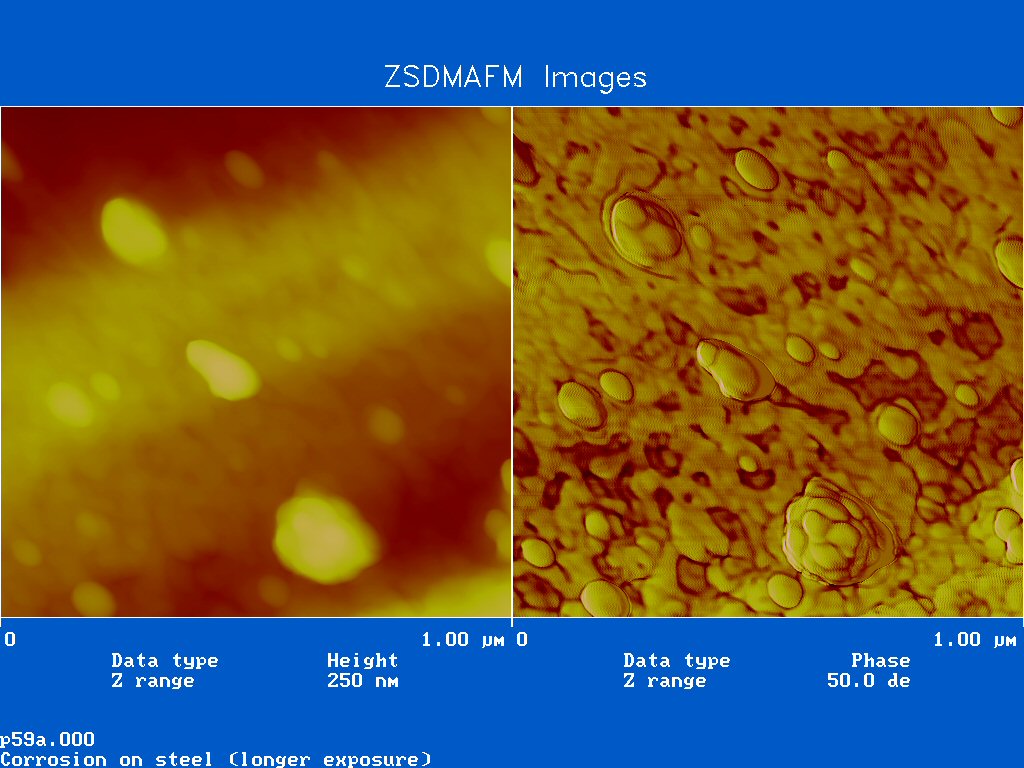

Corrosion

Many metals are used in harsh environments where corrosion is a concern. Understanding the process of corrosion allows engineers to develop ways to better control corrosion allowing for better part life and lower life-cycle costs.

These are just a few of the ways Atomic Force Microscopy can help engineers in the metals industry.