Rearchers at EMPA (Swiss Federal Laboratories for Materials Science) and EPFL (Ecole Polytechnique Federale de Lausanne) have created what appears to be the smallest motor in the world, consisting of a mere 16 atoms. A "rotor" consisting of a 4 atom acetylene molecule on a PdGa surface.

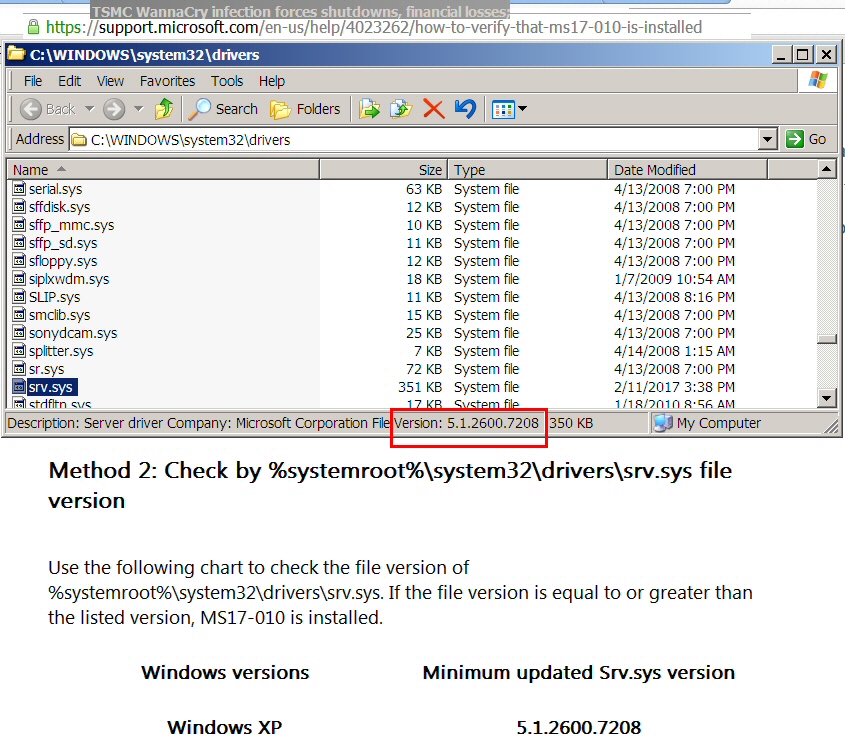

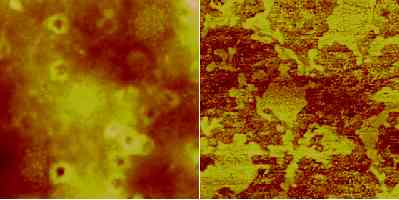

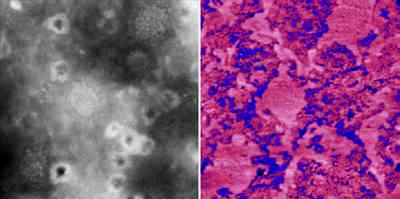

Researchers used scanning tunneling microscopy to observe the rotation of the acetylene molecule on the PdGa substrate.

The special feature of this "motor" is that it moves at the boundary between classical motion and quantum tunneling. The "rotation" isn't rotation as we think of it in the conventional sense. That is, the acetylene molecule doesn't smoothly turn form one position to the next. Instead it "quantum tunnels" from one position to the next without passing through the intermediate positions.

With quantum tunneling, which involves no energy loss, we would expect the motion to be random, that is movement "steps" would be clockwise as often as counter-clockwise. However, this one has 99% directional stability. Small amounts of energy (as little as from a single electron of current flowing into the motor) can cause the motor to rotate. Larger amounts of energy cause it to rotate faster (individual "steps" taking place more frequently) but increase the chance of the motor moving in a random direciton.

Thermal energy can also cause the motor to rotate but leads to random rotations. At room temperature the motor rotates randomly at several million revolutions per second.

The directionality brings up an interesting theoretical problem. Quantum tunneling is usually considered as being a lossless process. That is, no energy is expended in tunneling between two states. However, from thermodynamics, lossless processes are reversible. If is equally likely to go one way as it is to go the other. The directionality of the rotation of the acetylene molecule in this setup therefore indicates that there is some small loss in the tunneling process. Thus one application of this motor would be to help study energy loss in quantum tunneling.